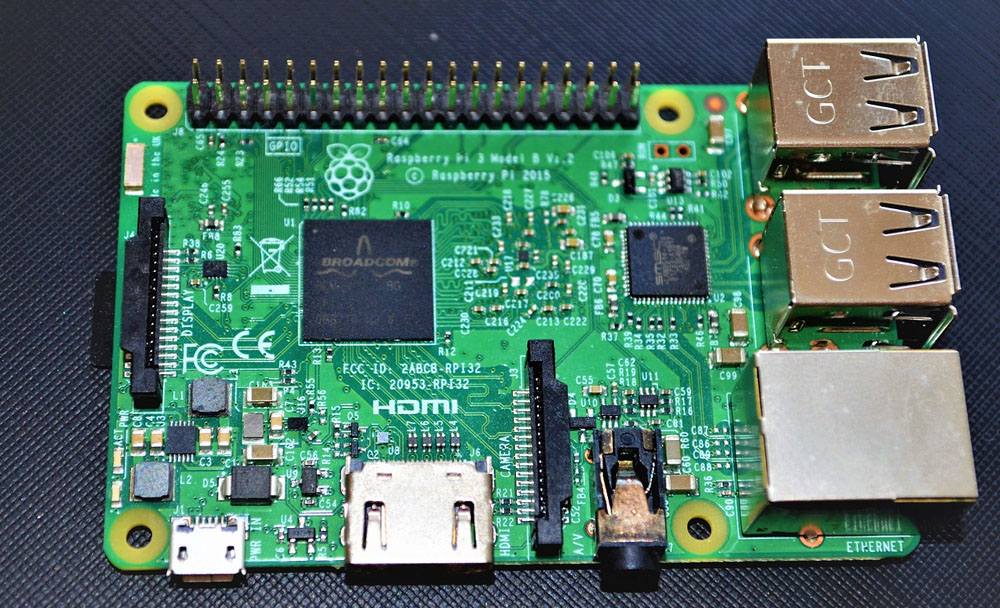

Desoldering is an invaluable skill that every electronics hobbyist needs. It’s particularly useful when you’re making repair or modification to printed circuit boards (PCBs), especially if you need to remove integrated circuits (ICs) to get rid of solder paste, copper pads, copper traces, or some other unwanted excess solder. Luckily, desoldering isn’t as hard as it sounds. With the right tools and techniques, you can learn how to desolder IC chips in no time. Let’s check out what these terms mean and how to desolder IC chip efficiently.

What is desoldering?

Desoldering is the process of removing solder from a joint by either removing the solder or the joint itself. When you remove the solder, you are cold-desoldering. When you remove the joint, you are hot-desoldering. Cold-desoldering is the process of removing a component from a circuit board without applying heat. Since there is no heat being applied to the joint, you need a tool that can pull the solder from the joint. Hot-desoldering is the process of removing a component from a circuit board while applying heat to the joint. This can be done with a soldering iron or solder sucker.

Why do you need to know how to desolder IC chips?

IC chips are usually surface mounted devices (SMD) on PCBs. They are also covered in solder paste. To remove them, you need to desolder them. And knowing how to desolder IC chips is crucial when you’re working on projects. You might need to desolder IC chips to replace them with new ones, or modify your PCB. Or the IC you’re using might be faulty and you need to remove it for repair.

What tools do you need to know how to desolder IC chips?

Soldering iron – A soldering iron is the most common tool used for desoldering. It’s a tool used in electronics repair, to join and re-flow components to PCBs. You can use a soldering iron with a desoldering pump (more on that below) to remove unwanted solder from a joint, or to remove a component from a circuit board. Desoldering pump – A desoldering pump uses suction to remove excess solder from your work area. It sucks out the solder and allows you to stay away from the iron. You can use a desoldering pump to remove a component from a circuit board. Soldering iron tip cleaner – The soldering iron tip cleaner is used to clean the tip of your soldering iron. The tip cleaner is a sponge that you apply the cleaning tip cleaner on and wipe the tip of the iron across it a few times. This cleans off any excess solder from the tip of the iron.

Desoldering tool tips and techniques

– Use a low heat when desoldering – The last thing you want when desoldering is to accidentally melt the PCB. Be sure to keep the soldering iron tip at a low heat and use the lowest setting your iron allows. – Pick the right solder tip size – Pick a solder tip size that’s larger than the pad or joint you’re trying to remove solder from. If your tip is too small, you run the risk of damaging the board. – Pick the right solder type – You’ll need to use a rosin core solder when desoldering. Choose a high-quality solder, and make sure it’s designed for electronics. – Clean off excess solder from the iron tip – If there is excess solder on the iron tip, it can transfer to the joint and pad you’re trying to remove the solder from. Make sure to clean the tip often to prevent this from happening. – Stay away from the iron when desoldering – While desoldering, stay away from the joint and pad you’re working on as much as possible. If you’re too close, you risk burning the board.

When you shouldn’t use desoldering equipment

– You shouldn’t use a soldering iron or solder pump to desolder SMD components that have been reflowed. You’ll likely end up with melted wires and other damage to the board. – You shouldn’t use a soldering iron or solder pump to desolder high-temperature parts. This can melt the part and damage the board. – You shouldn’t use a soldering iron or solder pump to desolder through-hole components. This can damage the part and end up damaging the board. – You shouldn’t use a soldering iron or solder pump to desolder old or brittle parts. This can break the part, increasing the risk of damaging the board.

Final Words

Desoldering is an important skill for every electronics hobbyist to know. It’s useful for removing unwanted solder, or even removing parts from a PCB. Using the right equipment and techniques is crucial for desoldering efficiently.

2022-11-18

2022-11-18